China's Greatoo eyes U.S. tire mold growth

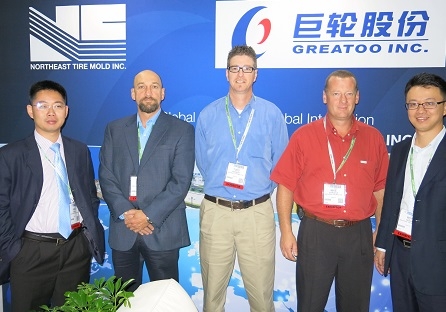

(Hong Zebin (from left), Christopher Sipe, Todd Keener, Michael Christie and Roy Hood pose at the Greatoo/Northeast Tire Mold booth during the International Tire Exhibition & Conference, held Sept. 9-11 in Akron.)

Chinese tire mold maker Greatoo Inc., which established a U.S. presence earlier this year by buying a 75-percent share of Northeast Tire Mold Inc., is planning to invest $20 million to relocate Northeast’s factory to a new site in Akron or the surrounding region.

The partners have not selected as site yet, according to said Roy Hood, director/sales manager for bothGreatoo and Northeast Tire Mold, but plans call for construction to begin next year and the new factory expected to open in early 2016 with an expanded capacity.

The forecast is for Northeast to produce sales of about $10 million in 2015 — representing about 700 tire molds — and for sales of 1,500 molds in 2016, Mr. Hood said.

Northeast has been in its existing plant in central Akron since the company’s founding in 1978.

Guangdon, China-based Greatoo paid an undisclosed amount in April for its ownership stake in Northeast Tire Mold, Mr. Hood said in an interview at the recent International Tire Exhibition & Conference in Akron.

Greatoo was formed in 1992. Besides making tire molds, it produces and markets curing presses, CNC machines and automation equipment, Mr. Hood said. It went public in 2004 on the Shenzhen Stock Exchange and employs more than 2,600.

He said Greatoo traditionally has been strong in China and other parts of Asia, and exported equipement to several countries in Europe and some areas in the Americas. The Chinese firm is strong in direct engraved molds and also utilizes casting and EDM technology.

By buying into Northeast, Greatoo not only gains greater access to the U.S. market, but it also joins up with a mold maker that focuses on the high-end of the tire market, he said.

“In the past, Greatoo sold some molds over here, but customers were saying it was better to have someone over here to help with repair and service,” said Mr. Hood, who is now based in Akron. “That is why we came together.”

Mr. Hood said the two mold makers approached each other and share the same business philosophies. “That is why we came together so quickly,” he said. “We want to be the No. 1 tire mold maker in the world.”

Mr. Hood said Greatoo has capacity to make 10,000 molds a year at its two plants in China. A factory in Tamil Nadu, India, can make 1,000 molds a year, but an expansion under way there will double capacity to 2,000 molds.

After buying into Northeast Tire Mold, Greatoo kept the management team at Northeast largely intact, including President Christopher Sipe and Vice President Michael Christie. Mr. Hood said some senior staff did choose to retire.

Northeast has been strong in North America, Mr. Hood said, and will look to export molds to South America from the Akron facility.

“They were limited by capacity in the past,” he said. “Sometimes when a customer wanted a mold, they couldn't deliver because of its size. Now they have the financial backing from us. We want to triple their capacity and even more. That will allow them to provide better service to the customers.”

There also will be opportunities to work together. Greatoo is building a high-tech mold shop at its facilities in China that will use the same programming, machinery and tooling package that Northeast will use, Mr. Hood said.

- Tireworld Insight: Domestic tire makers eye overseas expansion

- Tireworld Insight: Price disparity severe between China's rubber exports and imports

- Tireworld Insight: China tire exports dependent on US market performance

- Tireworld Insight: SHFE rubber expected to move in tight range in short-term

- Tireworld Insight: Rubber futures to test near-term resistance at 15,000 yuan/tonne

- Tireworld Insight: China’s tire industry on track of rapid growth